The timber tanalisation process involves forcing a preservative solution into the timber cells via a high vacuum pressure, ensuring longer-lasting protection against fungal decay and termite attack.

Step 1: Before the timber begins that tanalisation process it’s important that has been kiln dried or undergone natural drying methods. Packer are also used at this stage to allow a free-flow of preservative around the timber. Then the timber is put into the cylinder where an initial vacuum is applied to evacuate air from the cells of the timber.

Step 2: Treatment solution floods the storage tank under vacuum. The treatment solution consists of water and preservatives that help protect from fungal decay and termite attack.

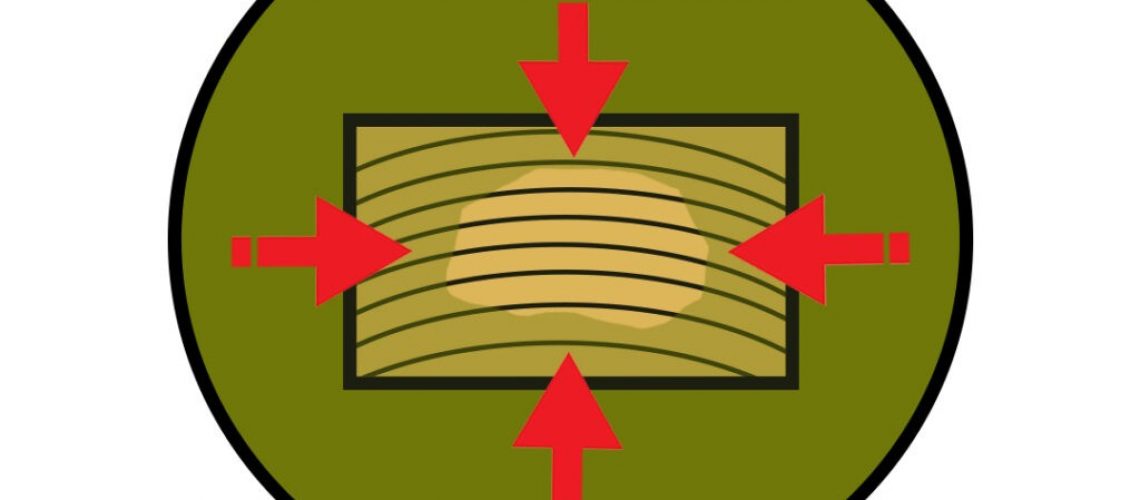

Step 3: Once the cylinder is full, the next step is to pressurise the cylinder with hydraulic pressure. the increased pressure forces the treatment solution into the wood.

Step 4: The remaining treatment solution is transferred back into a storage tank, along with a final vacuum extraction to remove any excess preservative solution.

Step 5: Final step involves being vented to normal atmospheric pressure. The low pressure helps draw the preservative solution.